- Home

- About Us

-

Applications

Municipal

Municipal Wastewater

Municipal water supply

Recycled Water Reuse

Township water supply and drainage

Industrial Park

New pollutant control

Water ecological restoration project

Municipal Wastewater

Municipal water supply

Recycled Water Reuse

Township water supply and drainage

Industrial Park

New pollutant control

Water ecological restoration project

Industry

Pretreatment of industrial high-difficulty wastewater

Pesticide Industry

API pharmaceuticals

Chemical waste salt purification

Food & Beverage Industry

Pharmaceutical Purified water

Chip Fabrication

Oilfield reinjection water

Industrial zero emissions

Pretreatment of industrial high-difficulty wastewater

Pesticide Industry

API pharmaceuticals

Chemical waste salt purification

Food & Beverage Industry

Pharmaceutical Purified water

Chip Fabrication

Oilfield reinjection water

Industrial zero emissions

Commercial

Secondary water supply

Pool & Aquarium

High-quality drinking water POE/POU

Aquaculture

Cooling Circulating water

Laboratory applications

Secondary water supply

Pool & Aquarium

High-quality drinking water POE/POU

Aquaculture

Cooling Circulating water

Laboratory applications

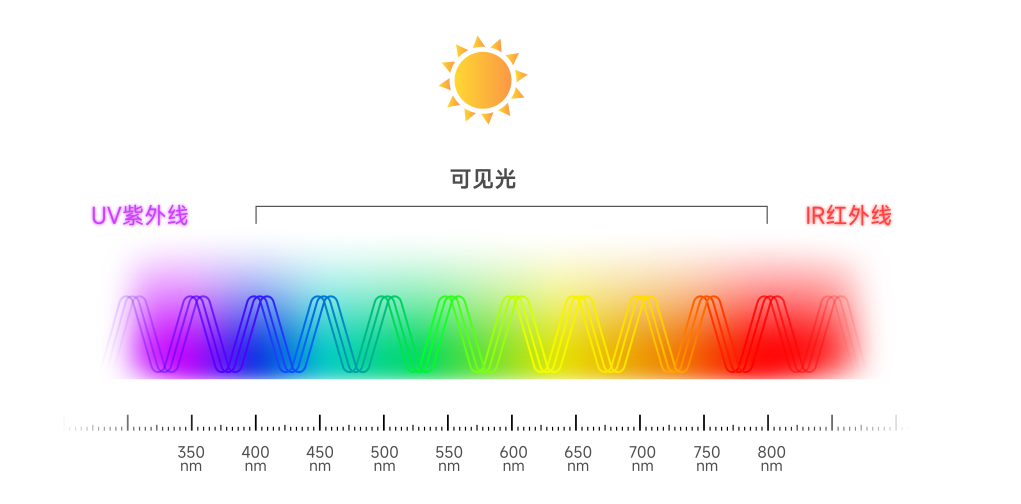

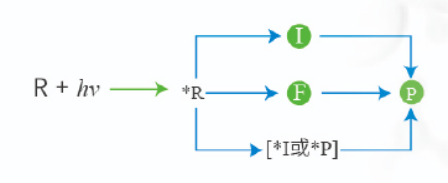

UV-AOPs

Wastewater Biodegradability

Pretreatment of highly toxic industrial wastewater

Chemical active agents

Cyanide

Organic Complexes

Wastewater Biodegradability

Pretreatment of highly toxic industrial wastewater

Chemical active agents

Cyanide

Organic Complexes

Craftsmanship

UV disinfection

UV photolysis

UV Advanced Oxidation

Reverse Osmosis

Alternative to pasteurization

UV photochemical reaction

Ozone oxidation

UV disinfection

UV photolysis

UV Advanced Oxidation

Reverse Osmosis

Alternative to pasteurization

UV photochemical reaction

Ozone oxidation

Resource Recycling

waste plastics

Construction waste

Renovation waste

waste plastics

Construction waste

Renovation waste

-

Products

Municipal

WSH UV Disinfection System

WTV UV Disinfection Vertical System

ZL UV Disinfection System

Clear Medium Pressure UV Disinfection System

MOL Ceramic Plate CD Ozone Generator

UV-AOP Advanced Oxidation System

D.FITE Cloth Filter

WSH UV Disinfection System

WTV UV Disinfection Vertical System

ZL UV Disinfection System

Clear Medium Pressure UV Disinfection System

MOL Ceramic Plate CD Ozone Generator

UV-AOP Advanced Oxidation System

D.FITE Cloth Filter

Industry

ZL UV Disinfection System

Clear Medium Pressure UV Disinfection System

UV-AOP Advanced Oxidation

Extrem Medium Pressure UV Disinfection System

EX-U UV Sterilizer

EX-UPW-TOC UV TOC System

MOM Ceramic Plate CD Ozone Generator

MOS Ceramic Plate CD Ozone Generator

UV-Fenton

UV-Oxidation

ZL UV Disinfection System

Clear Medium Pressure UV Disinfection System

UV-AOP Advanced Oxidation

Extrem Medium Pressure UV Disinfection System

EX-U UV Sterilizer

EX-UPW-TOC UV TOC System

MOM Ceramic Plate CD Ozone Generator

MOS Ceramic Plate CD Ozone Generator

UV-Fenton

UV-Oxidation

Commercial

EX-L UV Sterilizer

EX-U UV Sterilizer

ZL UV Disinfection System

CLEAR Medium pressure UV Disinfection System

OneUV UV Sterilizer

Extrem Medium pressure UV Disinfection System

UV-AOP Advanced Oxidation

MOS Ceramic Plate CD Ozone Generator

COG Ceramic Plate CD Ozone Generator

EX-L UV Sterilizer

EX-U UV Sterilizer

ZL UV Disinfection System

CLEAR Medium pressure UV Disinfection System

OneUV UV Sterilizer

Extrem Medium pressure UV Disinfection System

UV-AOP Advanced Oxidation

MOS Ceramic Plate CD Ozone Generator

COG Ceramic Plate CD Ozone Generator

Photochemistry

UV-Fenton

Medium-pressure UV-Oxidation

UV Photolysis

Pasteurization UV Alternatives

UV Photocatalysis

Low Pressure UV-Oxidation

UV-Fenton

Medium-pressure UV-Oxidation

UV Photolysis

Pasteurization UV Alternatives

UV Photocatalysis

Low Pressure UV-Oxidation

Resource Recycling

AI Optical Sorter

Al high-speed sorting robot

AI heavy-duty sorting robot

AI Optical Sorter

Al high-speed sorting robot

AI heavy-duty sorting robot

Others

SATBR Integrated Wastewater Treatment System

D.FITE Cloth Filter

Modular Wastewater Treatment System

ModuOzone Ceramic Plate CD Ozone Generator

SATBR Integrated Wastewater Treatment System

D.FITE Cloth Filter

Modular Wastewater Treatment System

ModuOzone Ceramic Plate CD Ozone Generator

- News

-

Services

After-Sales Services

Spare parts replacement

Product Repair

System Support

Renovation

Regular maintenance

Software Upgrade

Spare parts replacement

Product Repair

System Support

Renovation

Regular maintenance

Software Upgrade

Technical Support

Process Support

Product Training

Research & Development

Small Test

Pilotscale experiment

Online dose monitoring

UV dose design

Process Support

Product Training

Research & Development

Small Test

Pilotscale experiment

Online dose monitoring

UV dose design

Channel Services

Municipal

Industry

Business

OEM

Municipal

Industry

Business

OEM

Spare parts

Low Pressure lamps

Low Pressure Amalgam Lamps

Medium Pressure Mercury Lamp

VUV Low-pressure Mercury Lamp(185nm)

Quartz sleeve

Ballasts

UV Intensity Sensor

UV transmittance tester

Sealing accessories

Other

Spare parts replacement

Low Pressure lamps

Low Pressure Amalgam Lamps

Medium Pressure Mercury Lamp

VUV Low-pressure Mercury Lamp(185nm)

Quartz sleeve

Ballasts

UV Intensity Sensor

UV transmittance tester

Sealing accessories

Other

Spare parts replacement

- Resources

- Contact us

- Cn